The 7 Best Alteryx Competitors for Analytics Automation

Posts about:

According to a survey conducted by the Harvard Business Review, analytics automation increased manufacturing productivity by 90%, increased collaboration by85%, and reduced errors by 90%.

As organizations increasingly rely on data-driven insights to make informed decisions, the demand for efficient and comprehensive analytics software has reached new heights.

In 2026, the automation market is projected to surge to $9.36 billion, driven by a robust compound annual growth rate of 12.5%. Dataiku and Alteryx have emerged as leading solutions in this market, offering a wide array of capabilities and features to cater to diverse analytics needs.

In the industrial space, achievement is derived from the continuous enhancement of manufacturing processes. Executing these improvements effectively not only enhances product quality but also confers a distinct competitive advantage.

Siemens offers an integrated portfolio of software services and hardware equipment for the pharmaceutical industry, enabling efficient data sharing and collaboration across the entire pharmaceutical enterprise.

While Siemens aids in addressing business needs such as reducing cycle times and accelerating production, there are areas where additional solutions can optimize the process even further.

The pharmaceutical industry has a history of embracing technological advancements. Therefore, integrating advanced digital twin software has become essential to accelerate product development and meet new regulatory challenges.

Pharmaceutical companies often turn to Ansys to improve efficiency, as it excels in streamlining drug development, analyzing drug interactions, and designing efficient delivery systems.

Staying competitive in today's rapidly changing manufacturing environment and rapid development demands more than cutting-edge technologies or efficient processes.

To improve operational efficiency in manufacturing, process engineers and data scientists need a comprehensive strategy to maximize output, foster cooperation, and boost effectiveness.

Traditional machine learning (ML) systems often fail to address these professionals’ specific problems because they can’t provide real-time insights and bridge the gap between process engineering and data science.

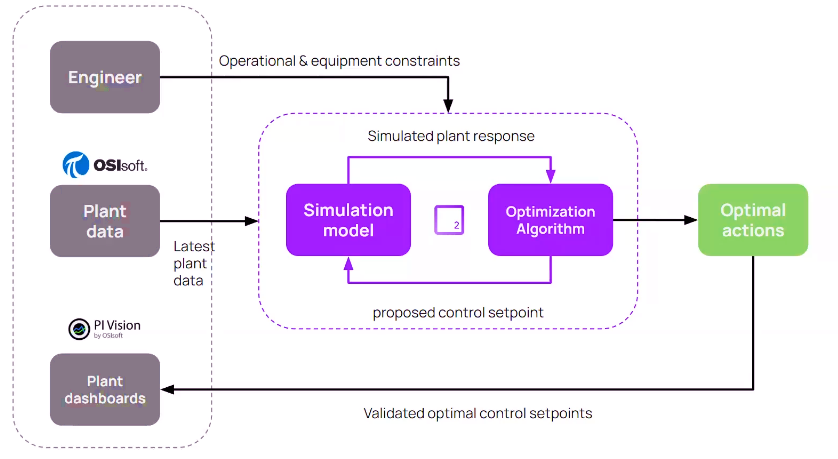

Hybrid modeling represents the intersection between traditional ML and the first principal engineering differential equations. By leveraging data in combination with engineering knowledge, modeling reliability can be highly improved for even biased and noisy industrial environments.

Figure 1:Hybrid model technology.

In this article, we will discuss operational efficiency in manufacturing and provide you with strategies, examples, and use cases that will help you improve your processes.

Finally, we will introduce Basetwo – a process optimization software that uses the power of physics-informed/hybrid machine learning to deliver unparalleled insights, revolutionizing how industry professionals gain valuable knowledge in real time.

“Global energy consumption and energy-related carbon dioxide emissions will increase through 2050 as a result of population and economic growth,” according to the International Energy Outlook study in 2021. “Adding a lot more renewable power and less coal to the mix will significantly lower the emissions associated with an expected 50% increase in energy demand”, says Stephen Rassenfoss from the Journal of Petroleum Technology.